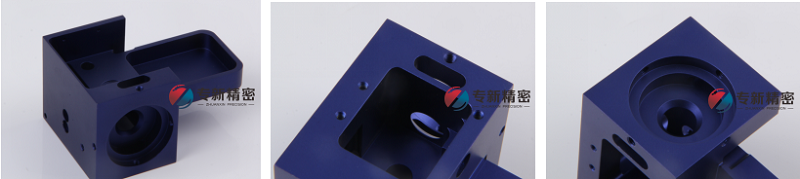

Name:CNC machining optical parts

Materials:Aluminium alloy

Technology:CNC machining

Surface:Blue anodizing

Allowance:+/-0.01mm

Number:500

Delivery:5

Product details

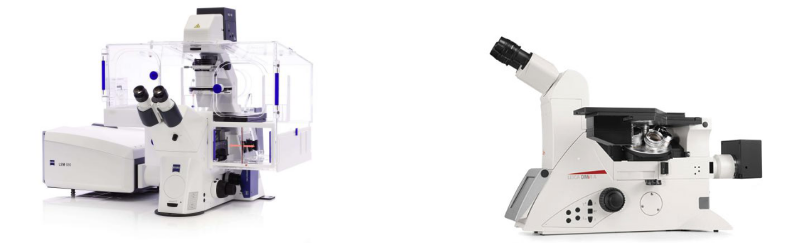

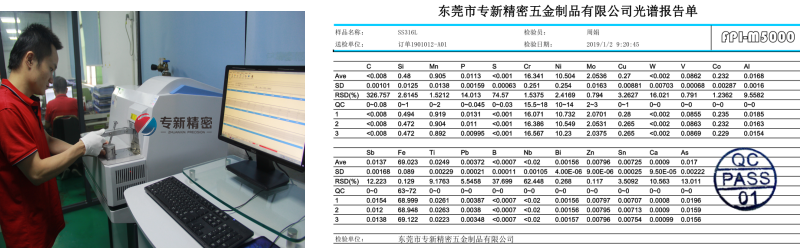

Optical equipment for parts processing accuracy, assembly accuracy, finish, extinction requirements are very high, so the engineers will choose to have high-precision production equipment, testing equipment and rich processing experience of CNC machining manufacturers to produce. We have many years of processing experience, imported CNC machining equipment, high-precision testing instruments (three-dimensional, quadratic, spectrometer, micrometer, etc.), we mainly have: Laser display, laser cinema, slide projector, camera, telescope, microscope, magnifying glass, melting point instrument, eyepiece, objective lens, UV irradiation meter, theodolite, level, color difference meter, spectrometer, photometer, tool presetting instrument, spectrometer, image instrument, projector, refractometer, etc.

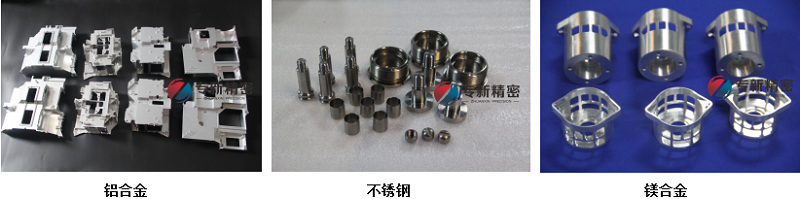

What materials are usually used in CNC machining optical equipment?

We provide CNC machining optical equipment services for Qingdao Hisense and other research and development optical equipment groups, and have processed countless optical equipment parts, and have a good understanding of the application of various materials. The common processing materials of optical equipment are: aluminum alloy, stainless steel, magnesium alloy, titanium alloy, zinc alloy, nickel alloy, copper parts, steel parts, etc.

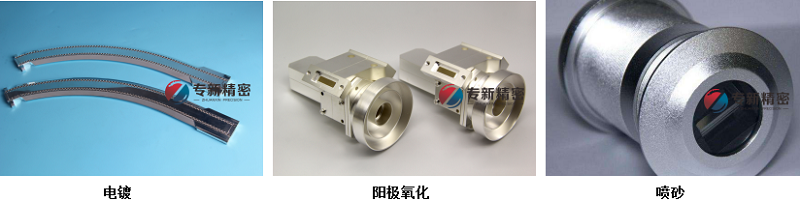

What surface treatment can CNC machining optical equipment do?

Do you want to increase the impression of your product? Want to make your product last longer? In order to give your designed products icing on the cake, the new precision can also provide you with supporting surface treatment, CNC processing optical equipment common surface treatment are: anodizing, electroplating, sandblasting, polishing, engraving, screen printing, spraying and so on.

The first inspection process - raw material inspection:

The type of metal material is very wide, it is difficult to distinguish from the surface, and the characteristics of different models are different, especially in the research and development test, using the wrong material may lead to problems in the entire research and development, a CNC machining manufacturer with rich processing experience and strict requirements for quality must have a spectral analyzer that can detect the material, in order to ensure the authenticity of the material. To ensure the normal operation of the product, the new precision spectrometer can test a variety of grades: steel, aluminum, copper, etc.

The second inspection process - Tool inspection:

When the programming master writes the CNC machining program, the first thing the operator has to do is to prepare the required tool in advance, and the new precision CNC operator will do one more thing -- first through the tool detector to detect the flatness of the tool blade, and the concentricity of the tool after the tool is installed into the tool head. The risk brought by the tool is controlled before the machining, and the step of detecting the concentricity on the CNC machine is eliminated, which improves the machining efficiency.

The third inspection process - operator self-inspection:

When the CNC program is finished, the operator will self-check on the machine to ensure that it is correct and then go to the next program or get off the machine to control the quality of each process.

The fourth inspection process - inspection:

Inspection personnel carry out sampling inspection of semi-finished products in processing, and once again ensure the qualified rate of products.

The fifth inspection process: full size inspection

According to the product shape and tolerance requirements, the quality department colleagues choose three dimensional, two dimensional, height meter, micrometer and other precision instruments to measure all dimensions of the product to ensure that the product size meets the requirements of customer drawings.

The sixth inspection process: post-processing and re-testing

Surface treatment is required for most products, but the product with strict tolerance requirements for electroplating will have a tolerance of 0.01mm, and the tolerance for spraying and painting will be about 0.05mm. Therefore, we will carry out dimensional inspection on all products after surface treatment again to ensure that the size after surface treatment is within the precision range required by customers.