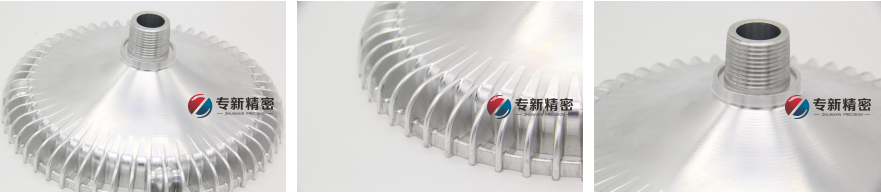

Name:Precision machining

Materials:Aluminium alloy

Technology:CNC machining

Surface:Light knife effect

Allowance:+/-0.01mm

Number:500

Delivery:15

Product details

What process does precision machining include? What accuracy can be achieved?

Precision product processing technology is necessarily complex and changeable, need to have a variety of process support, the new precision precision machining process is: CNC milling machine processing, CNC lathe processing, wire cutting, electric discharge, grinding, reaming, drilling, deep hole drilling, tapping, dental sleeve, etc., can process different kinds of products, specially designed for each product to develop suitable processing technology, accuracy can be controlled between 0.1~0.005(mm), to meet your product accuracy requirements.

What materials can precision machining process?

Precision products on the material requirements are also very high, different materials can achieve the accuracy is also different, in order to better serve customers in various industries, the new precision has a rich material library, up to 475 kinds, common materials are aluminum alloy, stainless steel, magnesium alloy, titanium alloy, zinc alloy, nickel alloy, copper, steel, and equipped with a spectrum analyzer, It is used to test the authenticity of raw materials, which can meet the customized needs of customers.

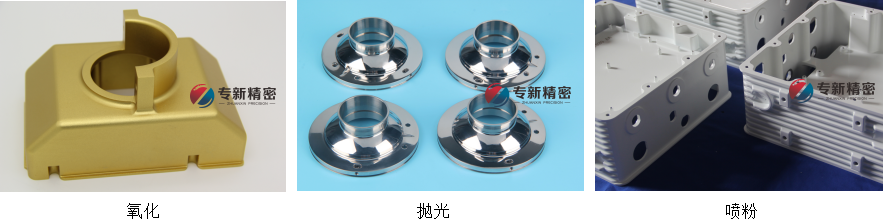

What are the surface treatments for precision machining?

In order to protect the product against rust and corrosion, or for the beautiful appearance of the product, it is usually necessary to make the corresponding surface treatment for the product; In addition to precision machining, the surface treatment also has a wealth of experience, common are: anodizing, sandblasting, electroplating, powder, painting, radium carving, screen printing, blackening, polishing, saving time and money for customers!

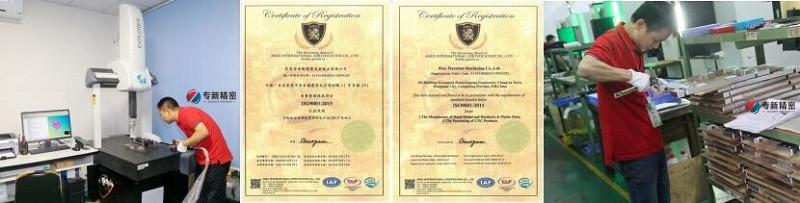

One: Quality assurance

Strict implementation of ISO9001:2015 quality management system, from raw materials to processing to shipping at least 6 inspection processes, do not let go of any quality loopholes, shipping pass rate of 98%!

Two: delivery guarantee

26 sets of CNC and other equipment 24 hours processing, good at dynamic milling technology, rough processing efficiency increased by 50%, each order has a professional training of the merchandiser personnel one-on-one follow-up, to ensure that the goods delivered to the customer within the scheduled time.

Three: production capacity guarantee

3000 square meters factory, the number of nearly 100 people, standardized production workshop, CNC computer gongs, CNC lathes, milling machines, grinding machines, automatic tapping machine, wire cutting, EDM and other equipment are available, the average monthly production capacity of 48,000 pieces.

Four: Service guarantee

Technical customer service staff 24 hours online, response within 30 minutes, solution within 2 hours, solution within 1 day; High-quality express companies such as SF Express and Leap-forward are used to follow up logistics information and ensure that products reach your hands safely.