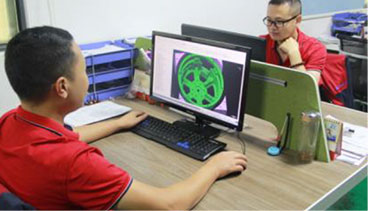

Customized machining process: NICECNC's engineering team customizes the most economical and reasonable machining process according to customer needs. For major projects, we will discuss with customers to provide constructive suggestions from the perspective of structure, material selection, surface treatment, etc. We do not feel difficult and cumbersome, just want to give customers the best help in new product development and CNC custom processing, and also improve ourselves.

More than 10 years of experience in engineering master programming, programming software: MASTERCAM,UG,POWERMILL, other engineering software: CAD, PROE,SOLIDWORKS. The new precision uses dynamic milling technology, which is 50% more efficient than the traditional CNC roughing, and 8 clamping technology patents are specifically for: complex products, precision products, and fast clamping of batch products.

Hardware material category model is wide, from the surface is difficult to distinguish, such as: SUS304 and SUS316, different models are different physical properties, special new precision processing before the use of spectral material analyzer to detect raw materials, to ensure that customers use real raw materials, the physical properties of the product requirements in the quality of a more heavy guarantee.

If you want to do something good, you must first sharpen your tool, when the programming master writes the CNC machining program, the first thing the operator has to do is to prepare the required tool in advance, and the new precision CNC operator will do one more thing -- the flatness of the tool blade through the tool detector before processing, and the concentricity of the tool after the tool is installed into the tool head. The risk brought by the tool is controlled before the machining, and the step of detecting the concentricity on the CNC machine is eliminated, which improves the machining efficiency.

When the CNC program is finished, the operator will self-check on the machine to ensure that it is correct and then go to the next program or get off the machine to control the quality of each process

Inspection personnel carry out sampling inspection of semi-finished products in processing, and once again ensure the qualified rate of products

For some special-shaped parts of complex parts, manual repair, to ensure that the product smooth without diamond, for precision parts and batch parts, the new precision advocates can be processed on the machine, as far as possible without manual processing.

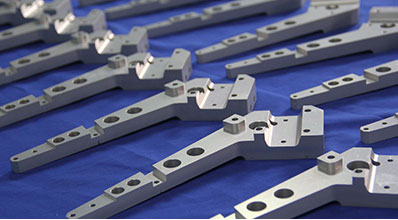

According to the product shape and tolerance requirements, the quality department colleagues choose three dimensional, two dimensional, height meter, micrometer and other precision instruments to measure all dimensions of the product to ensure that the product size meets the requirements of customer drawings

After the products are qualified by the quality department colleagues, according to customer needs to do the corresponding surface treatment, such as: sandblasting, oxidation, powder spraying, painting, electroplating, screen printing, radium carving.... Such as a variety of surface treatment, can be customized according to customer needs of various colors.

Oxidizing and electroplating products with strict tolerance requirements will have a tolerance of 0.01mm, and spraying and painting will have a tolerance of about 0.05mm. Therefore, we will conduct dimensional inspection on all surface treated products again to ensure that the size of the surface treated products is within the precision range required by customers.

After all sizes have been tested and qualified, we will take photos for customer confirmation before packaging and shipping. For some high-end products, we can provide customers with customized packaging with LOGO; For fragile or heavy products, reasonable and safe packaging methods can be customized, such as cartons or wooden boxes. We use SF Express to deliver goods within 12 hours in the same province and within 24-48 hours across provinces. In this era of developed Internet and logistics, distance is no longer a problem. Our customers have been all over Guangdong, Hunan, Hubei, Shanghai, Jiangsu, Shandong, Beijing, Tianjin, Inner Mongolia, and even overseas. Safe packaging and transportation are also responsible for the quality of our products, and we have a special person to follow up the logistics information to ensure that the product reaches your hands safely.

About how to optimize the design to reduce the cost of this machining

NICECNC combined with many years of processing experience to give the following design recommendations for your reference: