Name:CNC machining of nickel alloys

Materials:Nickel alloy

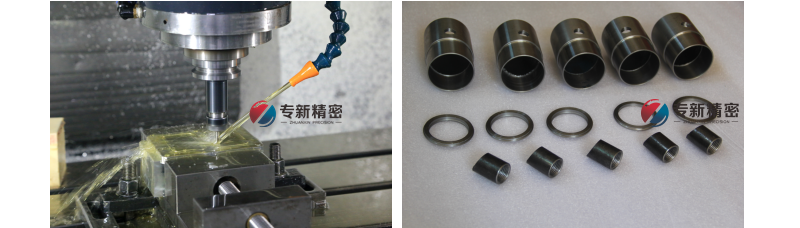

Technology:CNC lathe machining, CNC machining

Surface:Light knife effect

Allowance:+/-0.03mm

Number:500

Delivery:3

Nickel alloy is a special alloy material, its high temperature mechanical properties, corrosion resistance, wear resistance, heat resistance and some physical properties than the general alloy material is higher, when your product is used in a harsh environment, you can choose nickel alloy to improve the service life of the product, in recent years, nickel alloy products in the market more and more. CNC machining of nickel alloys has also become a necessary processing technology. Nickel alloy can be electroplated without copper substrate, which simplifies the process, achieves the purpose of cyanide-free electroplating, and improves environmental pollution.

Product details

What processing technology does CNC process nickel alloy?

Nickel alloy hardness is high, so the general process and ordinary tools are difficult to control, new precision has more than ten years of processing experience, can develop a reasonable processing technology for you, such as: CNC milling machine processing, CNC lathe processing, wire cutting, electric discharge, drilling, tapping and so on. No matter how many CNC machined nickel alloy parts you need, from 1 to 1000 pieces, NICECNC can be precisely customized for you!

Nickel alloy processing is difficult, high cost, not all industries are suitable for nickel alloy processing, CNC processing nickel alloy products for which industries?

1. Ocean: Marine structures in the Marine environment, seawater desalination, mariculture, seawater heat exchange, etc.

2. Environmental protection: thermal power generation equipment, wastewater treatment, etc.

3. Energy field: nuclear power generation, comprehensive utilization of coal, tidal power generation, etc.

4. Petrochemical field: oil refining, chemical equipment, etc.

5. Food field: salt production, soy sauce brewing, etc.

6. Heat treatment industry.

7. Bicycle, motorcycle and other industries.

8. Aerospace.

The environment of the above industries has relatively high requirements for materials, and more and more projects require higher grade nickel alloy materials.

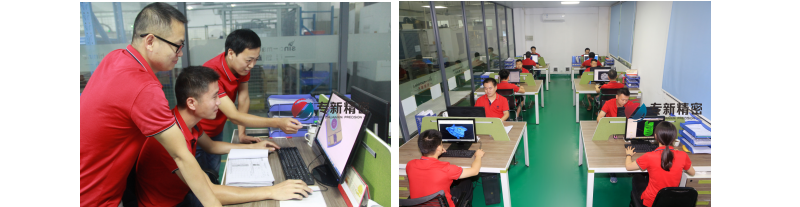

● ISO9001:2015 certification enterprise, 3000 square meters factory, 26 CNC and other equipment 24 hours processing, 48 hours receiving!

● 12 engineers with more than 10 years of experience provide technical consulting, pre-approval drawing files, structural analysis, risk assessment, constructive design suggestions, cost analysis and other services.

● From spectrum analyzer to three coordinates, from raw materials to finished products, at least 6 inspection processes, shipping pass rate reached 98%!

● Diversified custom processing, 475 kinds of materials +28 kinds of processing technology +21 kinds of surface treatment + custom packaging, from processing to shipping a series of customized services, save time and worry!

● 8 sales engineers online from 8 to 24, online quotation within 2 hours; Technical customer service staff 24 hours online, response within 30 minutes, solution within 2 hours, solution within 1 day!