The accuracy of CNC (Computer numerical control) machining technology depends on a number of factors, including the type of equipment, machining materials, tool selection, machining parameters, and environmental conditions. The following are some of the main factors that affect CNC machining accuracy and the typical machining accuracy ranges of different types of CNC equipment:

1. Main factors affecting machining accuracy

Machine quality: High-precision CNC machines typically use higher-quality components with better rigidity and stability.

Tool quality and wear: high-quality tools and timely replacement of worn tools are the key to maintaining machining accuracy.

Temperature control: Temperature changes in the processing environment can cause material expansion or contraction, affecting accuracy.

· Programming accuracy: Accurate CNC programming is an important factor to ensure high precision machining.

· Processing speed: Higher processing speed may affect accuracy, so it needs to be balanced according to specific requirements.

2. Machining accuracy of different types of CNC equipment

CNC lathes: Usually, the machining accuracy of CNC lathes is between 0.01 and 0.02 mm, and high-precision lathes can reach 0.005 mm or even higher.

CNC milling machine: The typical machining accuracy of CNC milling machines is between 0.01 and 0.02 mm, and ultra-high precision milling machines can achieve an accuracy of 0.001 mm.

CNC grinding machines: CNC grinding machines are usually used for machining requiring extremely high accuracy, up to 0.001 mm or more.

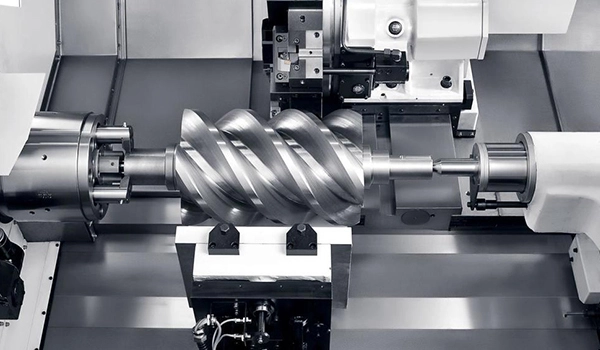

Five-axis CNC machine: This complex CNC machine can be machined from multiple angles, usually with an accuracy of 0.01 mm or more, depending on the brand and model of the machine.

3. Typical precision in industrial applications

Aerospace and defense industry: Very high precision requirements, usually need to achieve less than 0.005 mm accuracy.

Medical devices: In the manufacture of implants and surgical tools, accuracy requirements are usually within 0.01 mm.

· Automotive industry: The processing accuracy of some key components is required to be 0.01-0.02 mm.

Step 4 Summarize

CNC machining has a wide range of accuracy and is affected by many factors, but high-quality CNC machines and tightly controlled machining environments can achieve extremely high accuracy. Under normal circumstances, the accuracy of CNC machining can reach 0.01 mm, and even 0.001 mm in some high-precision applications.

Through the selection of the right equipment, optimization of processing parameters and strict quality control, CNC machining can meet the different needs of various industries for accuracy.